Some CPFR terminology in Demand Planning

CPFR – Collaborative Planning, Forecasting & Replenishment

CPFR – Collaborative Planning, Forecasting, and Replenishment is on a resurgence in many companies now. This was a popular buzzword in the late 90s but now companies that sell to retail are finding the value in CPFR – the ability to get insights into customer’s inventory and sell-through at retail so they could drive intelligent replenishments to avoid stock-outs!

The holy grail is to optimize the inventory at the customer’s backroom and shelf and get the power to take over the ordering of the product so the customer orders are in synch with your replenishment needs driven by the final consumer.

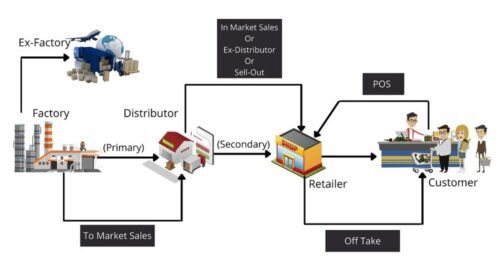

Interestingly this may go through multiple channels – you may at times sell to a distributor who sells to the retailer and finally to the consumer.

Here is a common glossary of terms used in CPG, Healthcare and technology sectors.

To Market Sales –

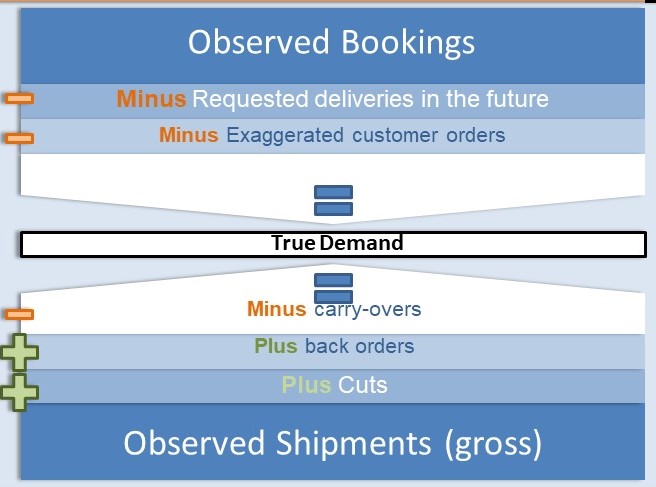

This is shipments from the selling company’s factory to the distributor, also known as ex-factory or sell-in data. This is the primary data as it originates from the plants and we have 100% visibility to what we invoice the customer and what we ship out.

In-Market Sales

These are shipments from the distributor to retailers and also known as sell-out or ex-distributor. This is secondary data. This may or may not be available to the manufacturer and depends on the systems and capabilities of the distributor. We have seen variations by the industry as well.

For example, beer companies provide their own systems to the distributors to manage their ordering and selling to their customers. This allows the brewers to get the sell-out data easily.

POS

This is the aggregation of what consumers like us will buy from Wal-Mart, Amazon.com, Target, CVS, etc. Detailed sell-through data is typically provided by the retailers to the manufacturers but this may also be available through syndicated data sources such as Nielsen.

If you have your own e-commerce offering through a company portal where you sell directly to the consumers, your POS day would be the same as To Market sales. Many variables such as online ads, positioning of the product on the web page may all affect the direct to consumer sales.

POS to Factory Shipments

Now it may look simpler to use POS but the POS data needs a lot of syntheses to cull out the useful information for the demand planner’s analysis. Companies that focus on POS or final sell-through for their business and sales planning will find themselves in a position where the supply chain needs a forecast of their To-Market sales. Process and systems need to be developed to convert the POS or final consumer sales to factor shipments.

This should take into account the volatility in channel inventory that could be caused by promotions, retail initiatives, and competitive dynamics.

Take the example of a product launch – channels will be loaded with pipeline inventories but the POS impact would be observed over 4- 8 weeks later in time. Though the process is generally to back out the To-market sales from the Sell-through forecast, at times the inventory load may spike the to-market sales ahead of the actual consumer sales.

Valtitude has deep expertise in helping clients implement CPFR systems and integrate CPFR into a holistic demand planning process. You can learn more details on our consulting at Value Chain Planning website.

Please contact us if you want to set up a complementary consulting session to discuss your specific needs.

Read More –