Managing Sales Order Deadlocks

If your company is concurrently experiencing growing backorders and ballooning inventory, you may be impacted by Sales Order Deadlocks. Sales Order Deadlocks occur when you have multiple orders with a ship complete designation that are all waiting on some inventory that is allocated to another incomplete order. That’s a lot to parse, so let’s break it down.

1. Ship Complete means that the entire order must be filled, or none of the order can be shipped.

2. Allocated inventory is something that is in stock and assigned to an order, which means that it’s technically not available to fill a different order.

3. The deadlock portion happens when multiple orders are partially filled and waiting on product that is in stock but allocated to other partially filled orders.

When this situation happens, then you’ll start to see inventory accumulate, back orders current orders grow, and revenue decline. If left unresolved, Sales Order Deadlocks create a supply chain bottleneck as inventory fills warehouses and inbound stock cannot be unloaded. These effects could easily be misconstrued to mean that demand is decreasing, which in turn could lead to inappropriate choices such as reducing purchases or other supply constraining activities.

Diagnosing the Sales Order Deadlock

Of course, there can be other causes that result in constraining outbound orders and growing inventory; be sure to look at sales order data and talk with your sales organization before drawing conclusions. If you have the orders, and your sales team is telling you the customers are anxious to get their product, then you’ll need to look to how your own sales order book is being managed.

Another clue that can point to sales order deadlocks is if you have recently experienced multiple concurrent stockouts. The more items you have out of stock concurrently, the more likely you are to experience deadlocks. As the volume of incomplete, back ordered sales grows, you are then more likely to experience allocation issues when the inventory you need starts to arrive.

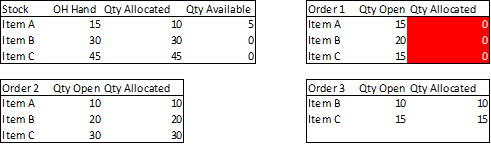

Figure 1 – Sales Order Deadlock Example

In Figure 1 we see a simple example of a sales order deadlock. If you have a reliable software platform for managing order allocation, this issue should be uncommon. But if you’ve done something to override standard allocation algorithms, such as making manual reservations, your order allocation algorithms may fail.

How to Respond to Sales Order Deadlock

There are many options resolving sales order deadlock, and the best solution depends on your circumstances. The alternatives you choose may require flexibility in negotiating with customers and working within your finance organization to accept margin deviation while you’re resolving the deadlock. If the deadlock has evolved into a overflowing warehouse, you may need help from warehouse managers to shuffle stock in and out of the warehouse to rebalance inventory.

Think of a sales order deadlock like a bottleneck at the point of demand – since most organizations are driven by demand, everything piles up behind the demand bottleneck until the issue is resolved. Here are a few options to consider in relieving the bottleneck:

• If you have a solid ERP, your best bet may be to cancel manual reservations and let your system re-plan the orders without interference. This could resolve the bottleneck, but it may not optimize short-term profit or address other strategic priorities.

• To achieve strategic priorities or profit optimization, you can escalate and deescalate orders based by rescheduling according to business priorities. Deadlocks can occur when all orders are equal priority, but if you push out some orders, your planning platform should reduce their priority and automatically reallocate to fill orders that need to ship sooner. The particulars of how this works may depend on how your system is configured.

• If orders cannot be executed because they are still waiting on a critical item, you can make deals with customers to cancel missing items, or separate missing items onto standalone orders so that the rest of the product can ship.

• In severe cases, such as the scenario portrayed at the start of this article, you may have to rebalance DC stock. That may involve moving excess stock into off site storage so that you can unload shortage stock and have it available to fill orders.

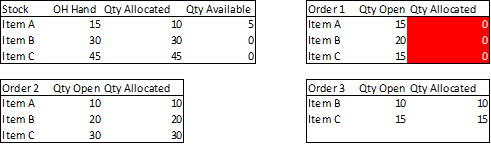

Figure 2 – Deadlock Example Resolved

Other Planning Considerations

Don’t forget that in demand driven organizations, the historical sales order performance is a key planning input into future expectations. If you have systematic issues fulfilling demand, such as a sales order deadlock, these issues can create false signals for forecasting. Be sure to assess side effects of a Sales Order Deadlock and address those to prevent future planning missteps.