SKU Level Forecasting OR Aggregate Planning – The Case For S&OP

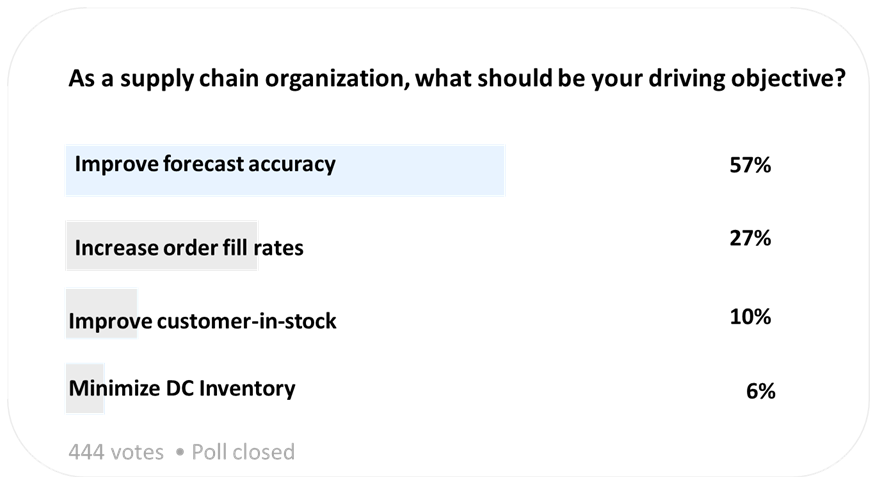

Talk to any supply planner, they will say they need a forecast at the SKU level. The more detail the better.

So the demand planner is on the defensive, he needs to forecast at the most granular level to satisfy the demands of the supply chain. Create and deliver a demand forecast at the SKU/location and sometimes at the SKU/customer/location level. But the more detail you get, the more noisy the data gets and it becomes impossible to create good statistical models at that level.

It is important to have a software package that allows you to get the forecast at that level. However, analyzing, reviewing and consensing at that level has its perils. Living too much at the detail level will definitely trap you from getting to the important challenges of the business and resolve true exceptions.

Looking at aggregate numbers for review and consensus among stakeholders leads to the Sales and Operations Planning process. Truly balancing Supply and demand at the aggregate level will result in driving the stakeholders to understand the true business problems.

Is demand equal to what we can supply?

Can we answer this question at the product family or sub-family level first? If not, can we smooth production so we build inventory to get ready for the peak demand?

If the answer is yes, then look at major MRP or schedule exceptions. But these should be addressed internally in preparation to the S&OP meeting. This is not a major S&OP decision.

Let us discuss more in a couple of weeks in Princeton, NJ.

http://www.demandplanning.net/demandplanning_tutorial_SIOP.htm.

According to classical theory planning should be at Aggregate level , but now a days company prefer to plan at SKU level . Why this so?

Yes. That is a valid approach. The challenge will be in identifying the clustering algorithm.

Secondly you also can use multi-variate approaches where if you have similar products that exhibit relationship to an external demand driver, then you model the demand as a function of the driver. In such a case, you could pool these observations to come up with a forecast driven by the causal driver.

Yes the more detail the best forecast, you need forecast at the sku level, aggregation is not an issue.

We do all our simulations at the sku level because we need true operations sim not ball park estimate.

You can play for free with our forecasting engine go and log on http://www.scgenius.com

I was just thinking about this very problem: forecasting for extremely noisy sku data. I haven’t done much forecasting in this arena before, but I had a thought about the process: What if you first ran a clustering algorithm to group together similar demand variables? So, if you’re an online retailer like amazon.com, you would probably find that most books tend to have one demand forecast (with peaks in holiday and before back to school) while technological products would likely peak in holiday only. After the clustering, do a time-series analysis on a non-noisy data set (either a product with alot of sales or an aggregate of some products). Then, project this forecast to individual sku levels. What do you think about this kind of an approach?