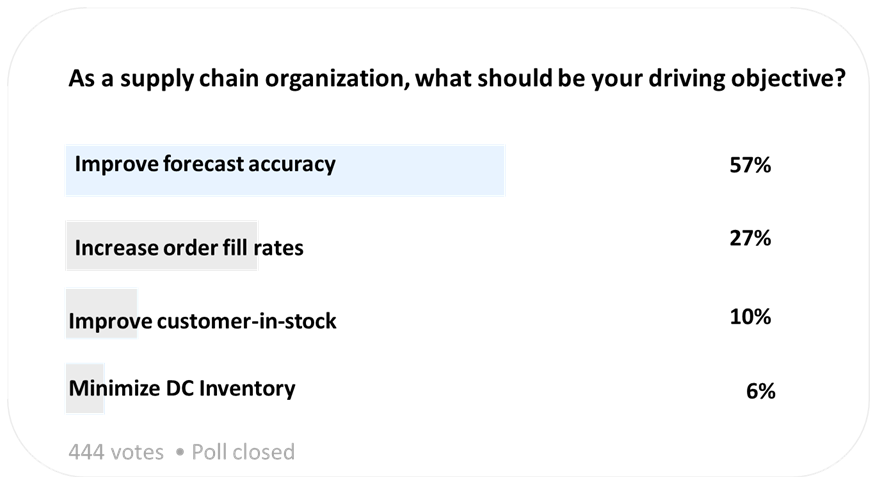

Forecast Error Benchmarking Across Various Industry – Survey Results

we started conducting the survey across supply chain and demand planning professionals from various industries. This survey was meant to compile information about their pain points, forecast error metrics they use, industry they work for, and who owns the demand planning function. We are publishing the first installment of the results from this survey in this newsletter.

As expected one of the metrics used by 52% of the respondents is WMAPE or volume weighted MAPE, calculated as Sum of Absolute errors divided by sum of actual demand.